Product Description:

Cold Work Tool Steel is a high-performance material widely used in industrial applications where durability, wear resistance, and toughness are essential. This specialized steel is designed to withstand extreme conditions during cold working processes, making it an ideal choice for manufacturing tools, dies, and molds that require exceptional strength and longevity. Our Cold Work Tool Steel product line offers superior quality and reliability for a variety of demanding applications.

One of the key benefits of our Cold Work Tool Steel is its excellent machinability, rated as fair. This means that while the material is robust and resistant to wear, it can still be machined efficiently using standard equipment and tooling. This balance allows manufacturers to achieve precise dimensions and intricate shapes without excessive tool wear or processing time, ensuring cost-effective production runs.

The material composition of our Cold Work Tool Steel includes 4140 alloy steel, a well-known grade renowned for its high tensile strength, toughness, and resistance to fatigue. The inclusion of 4140 alloy steel enhances the overall performance characteristics of the cold work tool steel, making it suitable for applications that demand both hardness and impact resistance. This makes our product line a reliable choice for fabricating alloy steel plates, alloy steel round bars, and other critical components used in heavy machinery and tooling industries.

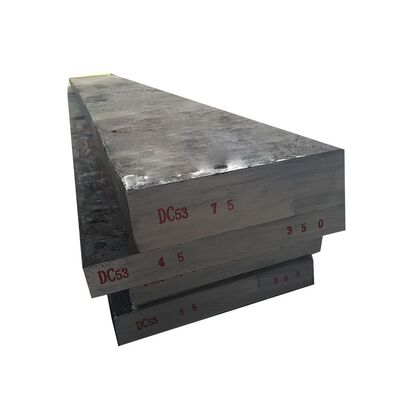

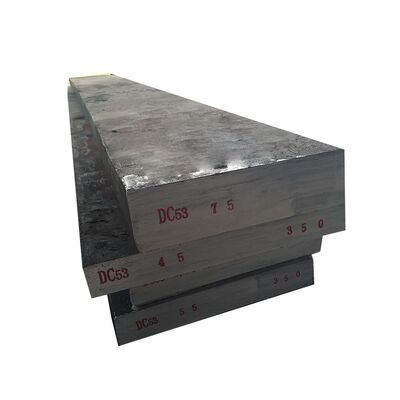

Our Cold Work Tool Steel is available in a wide range of sizes to accommodate diverse manufacturing needs. Round bars are offered with diameters ranging from 8 mm to 800 mm, while flat bars are available in thicknesses from 12 mm to 500 mm and widths from 100 mm to 1000 mm. This extensive size range ensures that customers can select the perfect dimensions for their specific projects, whether they require small precision tools or large structural components.

The delivery condition of our Cold Work Tool Steel products is flexible to suit different processing requirements. Customers can choose from black finish, milling, or fully machined conditions depending on their production needs. The black finish provides a cost-effective option for further processing, while the milling and machined conditions offer ready-to-use materials with precise surface finishes and dimensional tolerances. This versatility in delivery conditions enables manufacturers to streamline their workflows and reduce lead times.

When it comes to pricing, we offer competitive terms including EXW (Ex Works), FOB (Free On Board), and CIF (Cost, Insurance, and Freight). These flexible price terms allow customers to select the most convenient and cost-efficient shipping arrangements based on their location and logistical preferences. Whether you require shipment directly from our factory, through a port of origin, or delivered to your doorstep, our pricing options are designed to accommodate your needs.

In addition to its excellent performance characteristics, our Cold Work Tool Steel is rigorously tested to ensure compliance with industry standards for quality and reliability. This makes it a trusted material choice for applications involving high stress, repeated impact, and resistance to deformation. Its compatibility with alloy steel plate and alloy steel round bar forms further enhances its utility across various sectors including automotive, aerospace, construction, and heavy equipment manufacturing.

In summary, our Cold Work Tool Steel product offers a robust, versatile, and cost-effective solution for manufacturers seeking high-quality tooling materials. With fair machinability, a comprehensive size range, multiple delivery conditions, and flexible pricing options, it stands out as a reliable choice for producing alloy steel plates, alloy steel round bars, and other precision components. The integration of 4140 alloy steel ensures exceptional mechanical properties, making it an indispensable material for demanding cold work applications worldwide.

Features:

- Product Name: Cold Work Tool Steel

- Material: 4140 ALLOY STEEL

- Standard: JIS DC53

- Surface Treatment Options: Black, Peeled, Polished, Machined

- Density: 7.85 G/cm³

- Price Terms: EXW, FOB, CIF

- Service: 24 Hours Online Support and Free Sample

- High-quality 4140 ALLOY STEEL for durability and performance

- Reliable 4140 ALLOY STEEL ensuring excellent wear resistance

Technical Parameters:

| Material |

Cold Work Tool Steel (4140 ALLOY STEEL) |

| Available Stock Size |

20-500mm Diameter, 10-150mm Thickness |

| Available Size |

R: Dia 8-800; F: 12-500x100-1000 |

| Length |

3000-6000mm |

| Delivery Condition |

Black / Milling / Machined |

| Surface Treatment |

Black / Peeled / Polished / Machined |

| Production Technology |

Hot Rolled Or Forged Condition |

| Production Process |

EAF + LF + VD + ESR |

| JIS Standard |

DC53 |

| Price Terms |

EXW / FOB / CIF |

| Additional Information |

4140 ALLOY STEEL, ALLOY STEEL PLATE |

Applications:

Misung Steel, a renowned brand originating from China, offers premium Cold Work Tool Steel that caters to a wide range of industrial applications. This high-quality alloy steel plate and alloy steel round bar are specifically designed to withstand the rigorous demands of cold working processes, making them an ideal choice for manufacturing precision tools and components.

Cold work tool steel from Misung Steel is extensively used in scenarios where superior hardness, wear resistance, and toughness are critical. Typical application occasions include the production of cutting tools, dies, punches, and molds used in metal stamping, forming, and blanking operations. These products excel in environments requiring high strength and resistance to deformation under repeated stress, ensuring long service life and consistent performance.

The alloy steel plate and alloy steel round bar are also suitable for manufacturing shear blades, cold heading tools, and extrusion dies. Their excellent machinability and ability to maintain dimensional stability under cold working conditions make them indispensable in automotive, aerospace, and heavy machinery industries. The availability of surface treatments such as black, peeled, polished, and machined finishes provides flexibility to meet different processing and aesthetic requirements.

Misung Steel's Cold Work Tool Steel is supplied in various sizes, including diameters ranging from 20mm to 500mm and thicknesses from 10mm to 150mm, with available stock sizes of R: Dia 8-800 and F: 12-500x100-1000. This versatility supports customization and large-scale production needs. The product boasts a density of 7.85 G/cm³ and is certified as alloy steel, ensuring reliable chemical and mechanical properties.

With a minimum order quantity of just 1 ton and a competitive price range of 700-1200 USD per ton, Misung Steel ensures accessibility for both small and large-scale manufacturers. The company guarantees prompt delivery within 5 days, backed by a supply ability of 1000 tons per month. Payment terms include a 30% deposit with the balance payable before shipping, providing secure and flexible transaction conditions. Packaging options such as wooden boxes or pallets ensure safe transport and handling.

In summary, Misung Steel's Cold Work Tool Steel is an excellent choice for various cold working tool applications, offering robust alloy steel plates and alloy steel round bars that deliver superior performance, durability, and precision for demanding industrial scenarios.

Customization:

Misung Steel offers premium Cold Work Tool Steel products originating from China, specializing in ALLOY STEEL ROUND BAR and ALLOY STEEL PLATE customization services. With a minimum order quantity of 1 ton, our products are competitively priced between 700-1200 USD/TON, ensuring excellent value for high-quality steel.

Our Cold Work Tool Steel is produced using advanced processes including EAF+LF+VD+ESR, guaranteeing superior quality and performance. Certified standards are currently not available, but our supply ability of 1000 tons per month ensures timely fulfillment of your orders.

Available sizes include R: Dia 8-800 and F: 12-500x100-1000, catering to diverse industrial needs. The steel features fair machinability and is compliant with JIS standard DC53. Packaging is handled with care, using wooden boxes or wooden pallets to protect the materials during transit.

Delivery time is rapid, with products shipped within 5 days. Payment terms require a 30% deposit with the balance paid before shipping, providing a secure and straightforward transaction process. We also provide 24 hours online service and free samples to support your evaluation and project requirements.

Choose Misung Steel for reliable and customizable ALLOY STEEL PLATE and round bar solutions tailored to your specific needs.

Support and Services:

Our Cold Work Tool Steel products are supported by a dedicated technical support team committed to ensuring optimal performance and longevity of your tools. We provide comprehensive guidance on material selection, heat treatment processes, machining, and maintenance tailored to your specific application requirements.

In addition to technical advice, we offer a range of services including custom heat treatment, precision machining, and testing to meet stringent quality standards. Our experts work closely with customers to develop solutions that enhance tool durability, reduce downtime, and improve overall productivity.

We continuously invest in research and development to innovate and improve our Cold Work Tool Steel offerings. Our support extends throughout the product lifecycle, from initial design consultation to post-sale service, ensuring you receive the highest level of expertise and assistance.

For more detailed information on product specifications, handling instructions, or to discuss your unique application needs, please consult our technical resources or reach out to our support team.

Packing and Shipping:

Our Cold Work Tool Steel products are carefully packaged to ensure maximum protection during transit. Each steel piece is wrapped in rust-resistant paper and securely placed in sturdy wooden crates or reinforced steel pallets depending on the size and quantity. The packaging is designed to prevent moisture, corrosion, and mechanical damage.

For shipping, we coordinate with reliable freight carriers to offer timely and safe delivery worldwide. All shipments are accompanied by detailed documentation including product specifications, certificates of compliance, and handling instructions. We also provide options for customized packaging and labeling upon request to meet specific customer requirements.

FAQ:

Q1: What is the brand name of the Cold Work Tool Steel?

A1: The brand name of the Cold Work Tool Steel is Misung Steel.

Q2: Where is the Cold Work Tool Steel manufactured?

A2: The Cold Work Tool Steel is manufactured in China.

Q3: What is the minimum order quantity for this product?

A3: The minimum order quantity for the Cold Work Tool Steel is 1 ton.

Q4: What are the payment terms for purchasing the Cold Work Tool Steel?

A4: The payment terms are a 30% deposit with the balance paid before shipping.

Q5: How long does it take to deliver the Cold Work Tool Steel after placing an order?

A5: The delivery time is approximately 5 days after the order is confirmed.

Q6: What is the pricing range for the Cold Work Tool Steel?

A6: The price ranges from 700 to 1200 USD per ton, depending on specifications and order quantity.

Q7: How is the Cold Work Tool Steel packaged for shipment?

A7: The product is packaged in wooden boxes or on wooden pallets to ensure safe delivery.

Q8: What is the monthly supply capacity for the Cold Work Tool Steel?

A8: The supply ability is 1000 tons per month.

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!  ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร!

ข้อความของคุณจะต้องอยู่ระหว่าง 20-3,000 ตัวอักษร! กรุณาตรวจสอบอีเมลของคุณ!

กรุณาตรวจสอบอีเมลของคุณ!